Introduction on EN24 vs EN24T

EN24 vs EN24T are BS 970 standard steel grades. Here we compare their properties, applications, and performance to help you choose the right material for you or your customer.

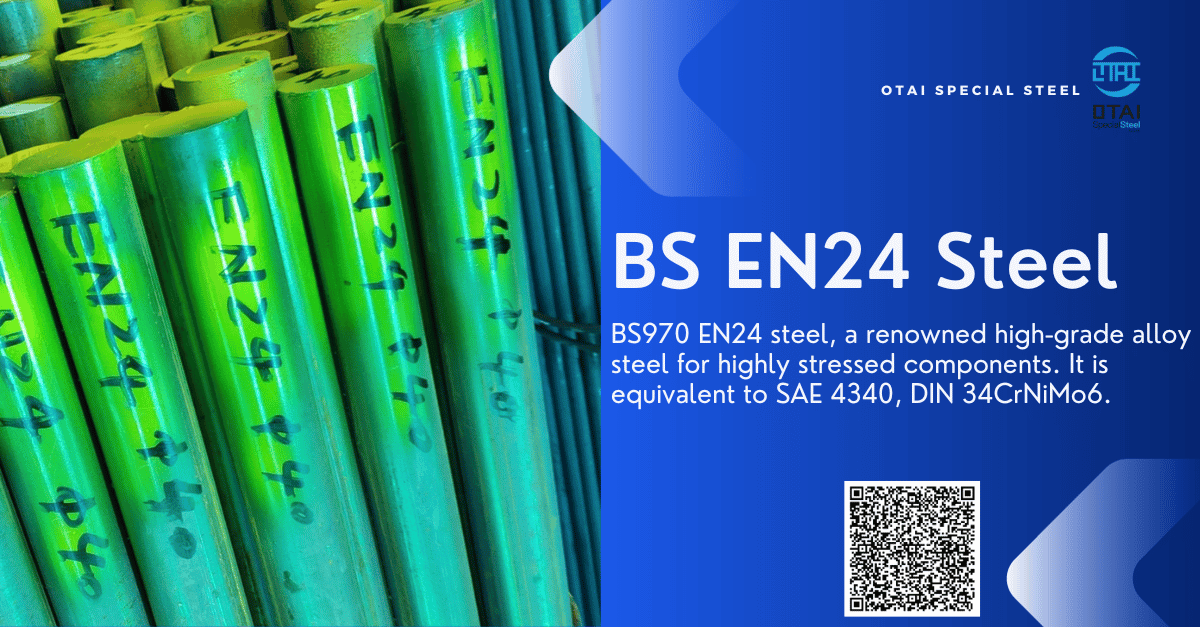

What is EN24 Steel?

BS 970 EN24, also known as 817M40, is a high-grade alloy steel known for its high strength and toughness. It is a chromium-molybdenum-nickel grade, which is widely used in industries where high tensile strength is a needed

Composition and Properties

EN24 steel is composed of various elements that contribute to its strength and hardness. The chemical composition is as below:

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| EN24 / 817M40 | 0.36-0.44 | 0.45-0.70 | 0.035 | 0.040 | 0.1-0.40 | 1.3-1.7 | 1.00-1.40 | 0.20-0.35 |

Applications of EN24

EN24 steel is extensively used in the manufacturing of gears, shafts, bolts, and fasteners. Its strength and resilience make it a good choice for parts which need high stress.

Understanding EN24T Steel

EN24T is a variant of EN24 but with an important difference: it is ‘T’ or ‘tempered.’ This heat treatment significantly enhances the steel’s strength and durability.

Heat Treatment and Enhanced Properties

Tempering EN24 steel means heating it to a certain temperature, holding it at that temperature for specific time, and then cooling it to achieve different properties requirements. The heat treatment increases the toughness of the steel without compromising its strength.

Why Choose EN24T?

EN24T’s upgraded toughness makes it suitable for even more demanding applications than standard EN24. It’s a better choice for parts that require high tensile strength and good ductility.

EN24 vs EN24T: A Comparative Analysis

Mechanical Properties

While both steels have high strength, EN24T has better toughness and ductility due to the tempering process. This makes EN24T more suitable for applications where the steel must endure high impact or stress.

Various Applications

- EN24 is well-suited for parts like bolts and shafts.

- EN24T, with its improved properties, is better for highly stressed components, such as gears and crankshafts in automotive industries.

Machinability

Both EN24 and EN24T have good machinability, but the heat treatment of EN24T can slightly change its machinability. The hardness and strength both make EN24T little difficult to machine.

Final

Choosing between EN24 VS EN24T depends on the specific requirements of your project or customer demand. Both steels offer high strength, but EN24T’s enhanced toughness makes it more suitable for applications which need higher stress and impact.

Either EN24 or EN24T is available here at Otai. We are professional supplier of those EN24 or EN24T alloy steel, as well as other tool steel. We offer you the best quality of EN24 & EN24T round bar and plate.

FAQs

1. Can EN24 be used in place of EN24T steel ? EN24 can be used in less demanding applications, but for higher stress request, EN24T is recommended.

2. Is heat treatment necessary for EN24T steel ? Yes, the ‘T’ in EN24T means tempering, which is important for its enhanced properties.

3. How does the toughness of EN24T compare to EN24 ? EN24T has superior toughness because of the tempering process.

4. Are there any specific industries where EN24T is preferred ? EN24T is widely used in the automotive and aerospace industries for manufacturing critical high-strength components.

5. What the price difference between EN24 vs EN24T steel ? As EN24T is with heat treatment tempering cost, so the price of EN24T would be higher than EN24 for sure.