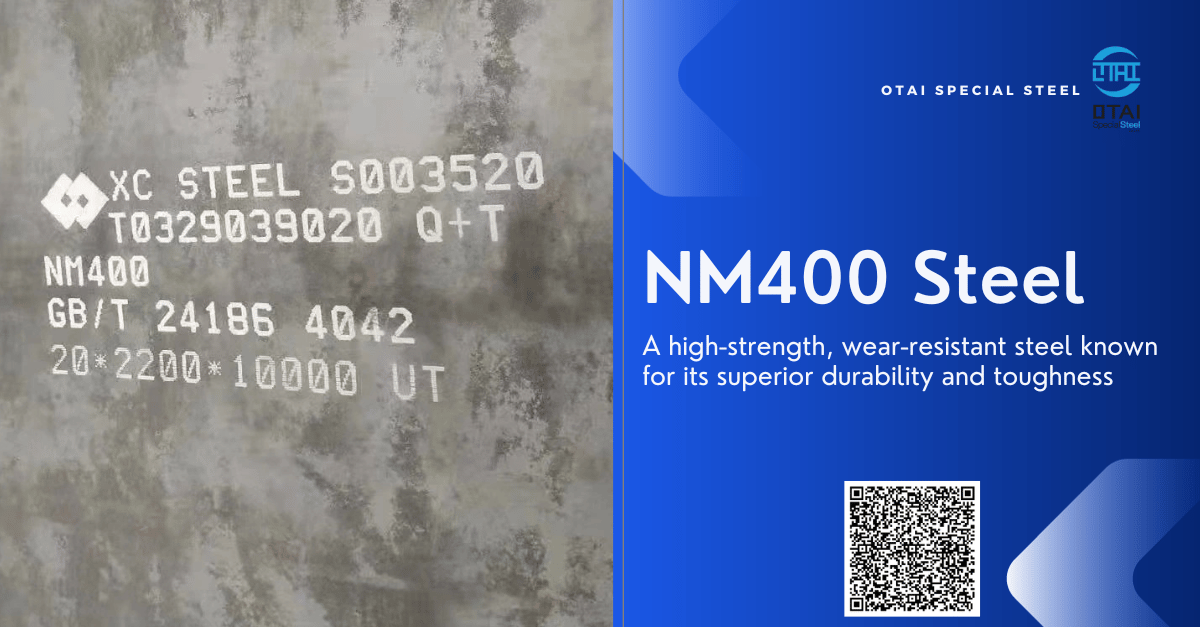

1. What is NM400 Steel Material

NM400 Steel is a high-strength, wear-resistant steel known for its superior durability and toughness. NM400 is a Chinese GB standard steel grade. The NM 400 material is widely used in industries where resistance to abrasion is important, such as in the construction and mining sectors.

Those abrasion resistant plate, like NM400 steel, NM450, NM500 wear resistant steel plate, has the following characters in details:

- Impact resistance: The impact resistance of the wear-resistant plate is very good. During the process of conveying materials, even if there is something drop from high place, it will not cause much damage to the wear-resistant plate like NM400.

- Heat resistance: Generally, NM 400 wear resistant plates below 600 degrees can be used normally. If we add some vanadium and molybdenum when manufacturing wear-resistant plates, it is even no problem to use those abrasion resistant plate NM400 at high temperatures below 800 degrees.

- Corrosion resistance: Because the NM400 wear-resistant steel plate contains a large amount of Cr, the corrosion resistance of the wear-resistant plate is excellent, and there is no need to worry about corrosion.

- Cost-effectiveness: The price of NM 400 wear-resistant plates is usually 3 to 4 times higher that of ordinary steel plates, but the service life span of wear-resistant plates is more than 10 times longer than ordinary steel plates, so those NM400 wear resistant plate / sheet is very cost-effective.

- Easy processing: The wear-resistant plate has very strong weldability, and it can also be easily bent into various shapes, making it very convenient to process.

2. Supply Range of NM400 Steel Plate and Sheet

- NM400 Wear Resistant Plate: thickness 3mm ~ 120mm x 1500~2300mm width x L

- Black Surface: Black surface

- Condition: QT (prehard condition)

3. Relevant NM400 Specification and NM400 Steel Equivalent Steel Grades

| GBT 24186 | JFE | SUMITOMO | DILLIDUR | SSAB |

| NM400 | JFE-EH400 | K400 | 400V | Hardox400 |

4. NM400 Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | B | Als |

| NM400 | ≤0.30 | ≤0.70 | ≤1.60 | ≤0.025 | ≤0.010 | ≤1.20 | ≤0.70 | ≤0.50 | ≤0.50 | 0.0005-0.006 | ≥0.01 |

5. NM400 Steel Mechanical Properties

Steel NM 400 sheet or plate is renowned for its exceptional properties, including high tensile strength, superior wear resistance, and excellent durability. These properties make it an ideal material for applications where high resistance to wear and tear is crucial.

| Mechanical properties of NM 400 | |||

| Grade | Mechanical Property | ||

| NM 400 | Yield | Tensile | Elongation |

| Min Mpa | Mpa | Min % | |

| 1000 | 1200 | 10 | |

| NM400 | Thickness | Hardness (HB) |

| ≤80mm | 370~430 | |

| >80~120mm | 360~440 |

6. Forging of NM400 Steels

Forging NM 400 plate / sheet involves heating the material to a specific temperature before shaping it. This process enhances the steel’s mechanical properties, making it more suitable for various applications. Proper forging techniques are crucial to maintain the integrity of NM400 grade steel.

7. Heat Treatment of NM400 Wear-Resistant Steel

Heat treatment of NM 400 sheet involves processes like annealing, normalizing, quenching, and tempering to enhance its mechanical properties. These treatments help in achieving the desired hardness and strength, making NM400 Steel more resilient to wear and tear. But for raw material supplying, we usually supply NM 400 plate in Q+T condition.

8. Application of NM 400 Plate

NM400 material plate is widely used in extensive applications in areas where durability and resistance to wear are paramount. It is commonly used in the construction of heavy machinery, mining equipment, and tools, owing to its ability to withstand extreme conditions and resist abrasion. Some typical applications are:

- Wear-resistant spare parts, such as high-efficiency powder selecting wear-resistant parts in cement machinery, mill steel plates, mixer blades, fan blades, mill rollers and so on.

- Various wear-resistant conveying pipes, such as powder air conveying system, blast furnace slag system, propeller blades, etc.

- Customized welding solutions for completing on-site construction projects, such as silos, chutes, large buckets, etc.

- Providing fabrication devices for on-site customized welding repairs to reduce on-site welding workload, such as buckets for work machines and dredging buckets for dredgers.

NM400 steel, with its remarkable wear resistance and high strength, is a go-to material for industries requiring robust and durable steel. For inquiries and price, please contact jeremy@otaisteel.com or via WhatsApp at +8613610149979 for a best quote price of NM 400 steel plates. We are your reliable supplier of nm400 steel plate.

FAQs:

- Is NM400 Steel suitable for heavy machinery construction? Absolutely, its high strength and wear resistance make it ideal for such applications.

- What is NM400 steel wear resistant steel price? Contact Dongguan Otai Special Steel at jeremy@otaisteel.com or via WhatsApp at +8613610149979 for reliable and quality NM400 material and best price.

- Can you supply 8mm wear resistant steel plate NM400? Yes, we can supply nm400 plate 8mm. We are able to supply nm 400 material from 3mm to 120mm actually.

- Are you NM400 steel plate factory? yes, we supply top quality NM 400 steel plate from top factories.

- What are the applications of NM400 abrasion-resistant steel? It is extensively used in heavy machinery, mining tools, and any equipment where high resistance to abrasion is required.