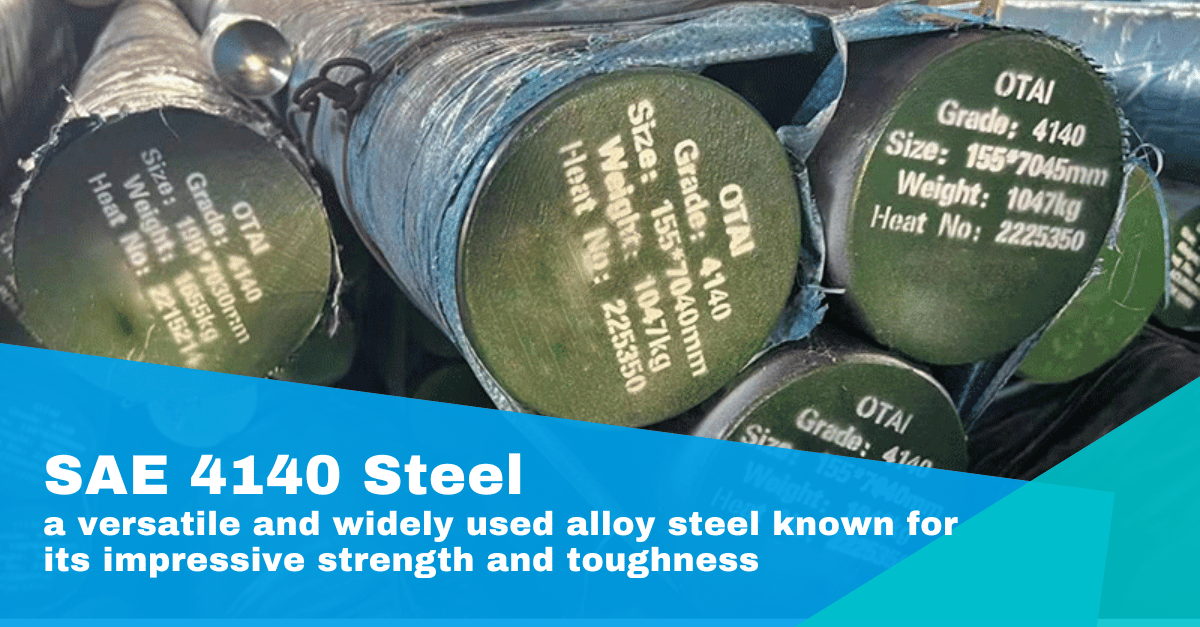

SAE 4140 steel is a versatile and widely used alloy steel known for its impressive strength and toughness. It belongs to the AISI/SAE A29 standard. Here we talk about different aspects of SAE 4140, including its chemical composition, mechanical properties, equivalent materials, and applications. Otai supplies SAE 4140 round bar and plate worldwide for over 20 years. We supply you right and reliable quality SAE 4140 steel.

SAE 4140 Chemical Composition

The chemical composition of SAE 4140 alloy steel is basic for its properties and applications. This 4140 alloy typically contains:

- Carbon: 0.38-0.43%

- Manganese: 0.75-1.00%

- Chromium: 0.80-1.10%

- Molybdenum: 0.15-0.25%

- Silicon: 0.15-0.30%

- Phosphorus: Max 0.035%

- Sulfur: Max 0.04%

Mechanical Properties of SAE 4140

SAE 4140 mechanical properties are what make it an excellent option for various industrial applications. Key properties include:

- Tensile Strength: Typically ranges between 655-740 MPa

- Yield Strength: Approximately 415 MPa

- Elongation: Around 25.7%

- Hardness: Brinell hardness of around 197

These properties can vary depending on the treatment processes like QT or annealig and normalizing. You tell us your special technical requirements, and our engineer would evaluate it and send you professional offer.

SAE 4140 Equivalent Materials

Sometimes SAE 4140 is not avaiable, or you are looking for alternative option with low cost and quicker delivery time, it’s also important to know those equivalent of SAE 4140 steel material:

- AISI 4140

- EN19 (European Standard BS 970)

- 42CrMo4 (European Standard EN 10083)

- SCM440 (Japanese Standard JIS G4105)

Each of these equivalents maintains similar chemical compositions and mechanical properties. Generally the price of SAE 4140 is highest than other equivalents while 42CrMo4 is the grade which is easiest to get.

AISI 4140 vs SAE 4140: Understanding the Differences

While AISI 4140 and SAE 4140 are often used interchangeably, it’s important to understand their nuances.

have slightly different standards for steel grading.

However, for 4140 steel, both AISI and SAE specifications are actually identical.

AISI 4140 Annealed Properties

Annealing AISI 4140 steel significantly changes its properties. Annealing makes SAE 4140 easier to machine and less brittle. The annealing process means to heat the SAE 4140 alloy steel and cooling it slowly. After annealing, we get lower hardness and increased ductility.

SAE AMS 4140 and ASME Equivalents

SAE AMS 4140 refers to the aerospace material specifications for this alloy, indicating its use in the aerospace industry. The ASME (American Society of Mechanical Engineers) also recognizes 4140 steel, often in applications requiring high strength and resilience. So, even though the standards are different, the 4140 chemical composition and properties are same. Just for different industry application, different organization or association make different standard.

Applications of SAE 4140 Alloy Steel

SAE 4140 is widely used in the automotive, aerospace, oil and gas, and manufacturing industries. Its applications range from gears and shafts to bolts and fasteners. The steel’s high fatigue strength and resistance to wear make it ideal for high-stress applications.

Choosing the Right SAE 4140 Product

When selecting SAE 4140,

- Decide on the shapes of 4140 steel, such as AISI 4140 flat bar or SAE 4140 round bar. It depends on your needed size.

- What heat treatment do you require or what properties do you need? If you just need normal condition for general application, SAE 4140 as rolled / hot rolled condition meets your requirement. However, if you need higher mechanical properties, you would need treatment processes like annealing, normalizing or QT (quenching and tempering) heat treatment on 4140 steel materials.

- Surface condition or tolerance you need. For raw materials of 4140, we just supply black surface with +/-1mm tolerance. However, if you need special tolerance, we could machine it and deliver to you machined surface SAE 4140 steel materials either 4140 steel plate or round bar.

Final

SAE 4140 steel is an essential material in engineering and manufacturing. It offers a balance of strength, toughness, and versatility. Its wide range of applications and the availability of equivalents like AISI 4140 make it a popular choice among professionals. Otai is one of top alloy steel and tool steel supplier like SAE 4140 steel, SAE 4340, SAE 8620 steel. Any inquiries, contact us any time and best price with all detailed terms.

FAQs About SAE 4140 Steel

- What industries primarily use SAE 4140 steel?

- SAE 4140 is extensively used in automotive, aerospace, oil and gas, and heavy machinery industries.

- Can SAE 4140 steel be welded?

- Yes, SAE 4140 can be welded, but it requires preheating and post-welding treatments to maintain its mechanical properties.

- How does annealing affect AISI 4140 steel?

- Annealing reduces hardness and increases ductility, making AISI 4140 more machinable and less brittle.

- What is the primary difference between AISI 4140 and SAE 4140?

- There is minimal difference; both refer to the same steel grade with similar specifications.

- Is SAE 4140 steel suitable for high-temperature applications?

- Yes, due to its high fatigue strength and toughness, SAE 4140 is suitable for high-temperature applications.