NAK80 steel is a precipitation or age-hardened mold steel with a uniform through hardness of approximately 40 HRC. It is super clean, Vacuum-Arc Remelted steel with uniform grain structure, uniform hardness, and excellent dimensional stability. NAK80 tool steel is the improved steel grade of NAK55, on mirror surface, EDM surface and toughness.

There are unique characteristics for JIS NAK80 steel:

- Super clean, Vacuum-Arc Remelt manufacturing process.

- 40 HRc hardness.

- Age-hardened for uniformity of hardness throughout, even in heavy sections.

- When welded, NAK leaves no witness lines after re-aging.

- Uniform grain structure with no pin holes, inclusions or hard spots.

- Machines up to 20% faster than 30 HRc P20 mold steels.

- Never needs stress relieving, even after heavy machining.

- Polishes to a superior No. 1 finish, even over welded areas.

Otai special steel supplies NAK80 mold steel for your high end requirement of plastic mold steel. You have the following technical properties of NAK80 tool steel and you are welcome to send us your request of NAK80 tool steel anytime.

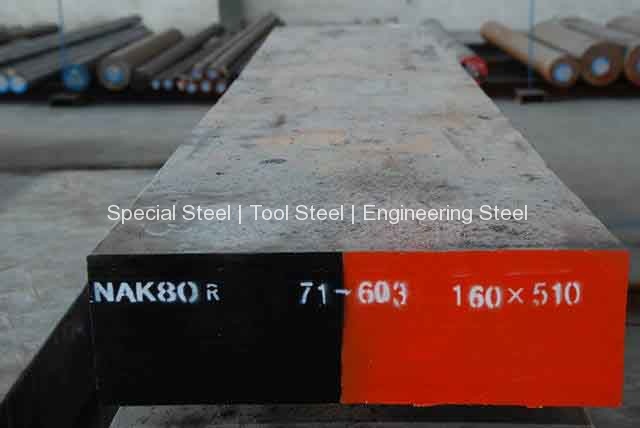

1. JIS NAK80 Mold Steel Supply Range

JIS NAK80 Steel Round Bar: 8mm-800mm

NAK80 Steel Cold Drawn Bar: 5mm-70mm

NAK80 Steel Plate: 10-600mm x 200-3000mm

2. Mold Steel NAK80 Equivalents and Chemical Composition

| JIS | C | Si | Mn | Ni | Cu | Mo | Al |

| NAK80 | 0.15 | 0.30 | 1.50 | 3.00 | 1.00 | 0.30 | 1.00 |

| GB/T | C | Si | Mn | Ni | Cu | Mo | Al |

| 10Ni3MnCuAl | 0.06-0.16 | 0.40 | 1.4-1.7 | 2.7-3.3 | 0.8-1.2 | 0.2-0.5 | 0.7-1.2 |

| ASTM A681 | C | Si | Mn | Ni | Cr | V | Al |

| P21 | 0.18-0.22 | 0.2-0.4 | 0.2-0.4 | 3.90-4.25 | 0.2-0.3 | 0.15-0.25 | 1.05-1.25 |

3. JIS NAK80 Steel Physical Properties

- Physical properties (avarage values) at ambient temperature

- Modulus of elasticity: 30 x 106 psi

- Density [g/cm3]: 7.72

- Thermal conductivity [W/m.K]: 41.3 (100oC), 42.2 (200oC)

- Maximum magnetic permeability: 380

- Saturated magnetism (Gauss): 16,360

- Residual magnetism (Gauss): 8,500

- Coercive force (Oersted): 14.0

4. JIS NAK80 Steel Hardness

The precipitates, which account for the steel’s hardness, begin to grow in size if the original hardening temperature range for NAK80 steel (932°-950°F) is exceeded for an extended period of time. This results in a loss of hardness and toughness, accompanied by dimensional change.

Re-solution heat-treating and subsequent precipitation hardening can recover hardness and toughness, but dimensional changes will have occurred.

5. Heat Treatment of JIS Steel NAK80

- Soft Annealing

Heat NAK80 steel to 640-660oC, cool slowly. This will produce a maximum Brinell hardness of 330.

- Hardening

Harden steel NAK80 from a temperature of 880-900oC followed by oil quenching. Hardness after quenching is 41 HRC.

- Age-Hardening

Heat up to 550oC with heating speed 60oC/h, then hold 5 hours at temperature and then cool slowly in the air.7. Stability

6. Stability of NAK80 Mold Steel

NAK80 steel is not quenched to achieve hardness. Therefore, it does not have the stresses inherent in quenched and tempered steels. Tool steel NAK80 never needs stress relieving due to heavy machining because of uniform hardness throughout. It has excellent dimensional stability during mold construction and while in service. Even after long mold runs, cool-down, and subsequent re-heating, the material maintains dimensional stability.

7. Nitriding of Steel NAK80

NAK80 plastic mold steel contains 1% aluminum and responds very well to nitriding. There are many forms of nitriding and each has advantages. However, for molding die applications, ion-nitriding, in particular, is very suitable for NAK80 tool steel. When employing standard gas nitriding, do not exceed 950°F.

The ion-nitriding process is done in a controlled atmosphere. It is clean, with minimal distortion, and can be done at temperatures that do not damage NAK80 tool steel.

Nitriding increases wear resistance and creates a hard surface ideal for slides or dies that mold abrasive or mineral-filled thermoplastics. The nitrided surface has a hardness over 60 HRc, improved corrosion resistance, and can be polished to a finer finish than possible at base metal hardness.

8. Application of NAK80 Mold Steel Materials

NAK80 steel is mainly used for plastic molds for the following

- Transparent products and others for which mirror finished surface are particularly important

- Products for which electrical discharge machined surfaces are very important

Typical for clear lens molds, extremely critical diamond finish applications, and molds requiring special EDM finish.

Contact Otai Steel for more information about the NAK80 steel price and promotion time to time. We are a better choice for you.